-Cytokines

-Carrier proteins

-Recombinant polypeptide

-Recombinant enzymes

-Allergens

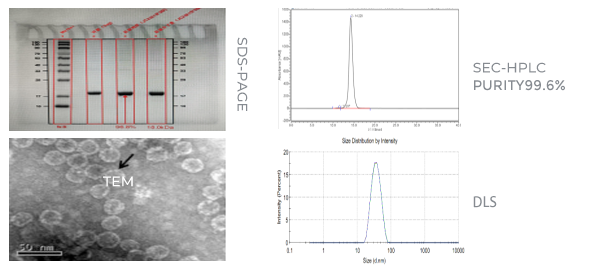

-VLPs

-Vaccines

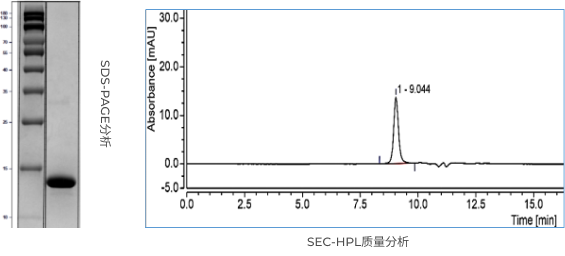

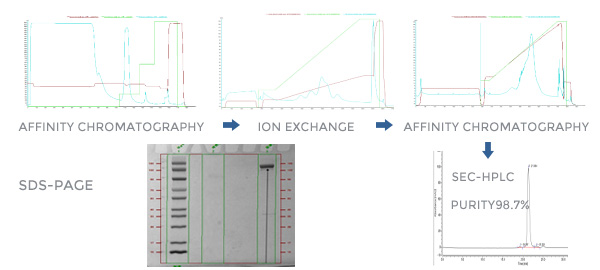

-Mature unlabeled protein process development capabilities to reduce process steps, improve protein purity, and ensure that process impurities and product impurity residues are qualified.

-The localization of critical materials and equipment to save cost, platform-based processes to respond quickly to meet project requirements and shorten process development period.